Virtual Tour

Spring Point Ledge Lighthouse is one of 49 caisson lighthouses built in the United States and it is the only one that is accessible from land. This is due to its location at the end of the 950-foot breakwater that extends into the harbor from the grounds of Fort Preble on the campus of Southern Maine Community College in South Portland.

Completed in 1897, the lighthouse has been intertwined with the history of Casco Bay and Portland Harbor, providing guidance to ships and boats transiting the harbor around the dangerous ledge on the end of which the lighthouse sits. The lighthouse has become a symbol for the City of South Portland, is seen daily on local television broadcasts, and is visited by thousands of people from all over the world each year.

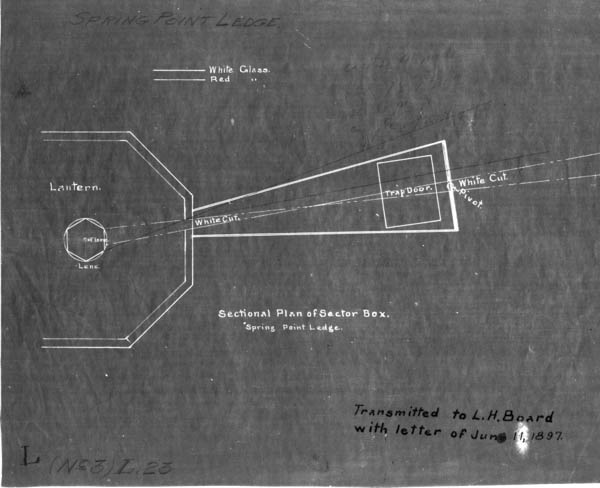

Spring Point Ledge Lighthouse has several unique features that distinguish it from other lighthouses of its type. Its upper works are brick instead of the usual cast iron construction, probably as a concession to the harsh winters experienced in Maine. The other unusual feature was the sector box. To date, the Trust has not located another lighthouse that had this structure attached.

During the summer of 2020, the Trust developed a series of videos to give would-be visitors a virtual birdseye view of the lighthouse and its charming characteristics.

Explore more of the unique features of the lighthouse and learn about its structure and functions below. You will meet one of the keepers and learn how they lived on a turn-of-the-century lighthouse. The Spring Point Ledge Light Trust hopes that after exploring the lighthouse virtually, you will come and explore it in person.

BREAKWATER FACTS

- Construction began in 1950; completed in 1951

- Cost of construction: $215,000

- Stone was quarried in Biddeford and Wells

- Total length: 875 feet

- Height: 15 feet at low water, 6 feet at high water

- Side slope: harborside ~1:1; seaside 2:1

- Stone: granite, 75% in 5-ton blocks, 25% in 3-ton

- Built by US. Army Corps of Engineers

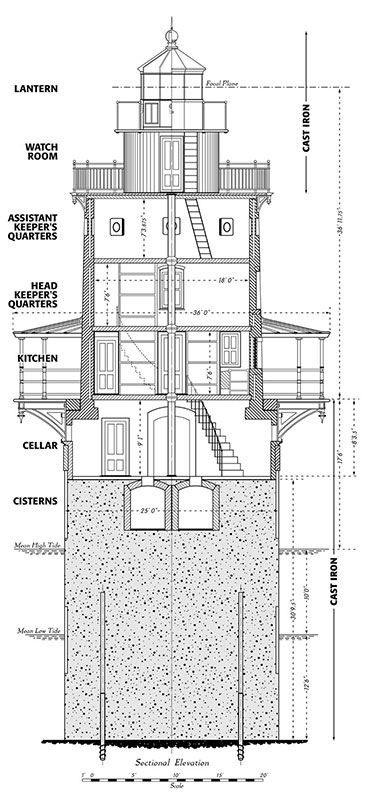

The basement level of the lighthouse was also referred to as the first floor, even though we now think of the galley level as first. The basement is actually contained within the cast iron cylinder and, thanks to the height of the breakwater, visitors are actually standing even with the basement level when next to the lighthouse.

The basement is lined with brick to a thickness of around 24 inches. There were three small windows in the cylinder, but most have been sealed in recent years. There was also a hatch near the basement ceiling on the east side to permit coal to be transferred directly into the basement from a supply barge or boat alongside. There are also two small storage closets and a small room that might have functioned as a workshop or supply room for performing routine maintenance on the lighthouse

The center of the basement floor holds a cement pad that probably held either a compressor or a small generator. The actual use is uncertain, though the Trust is attempting to ascertain the exact purpose of the pad.

The most remarkable features of the basement are two brick-lined cisterns embedded in the basement floor. These cisterns held the only water supply for the lighthouse. Water was collected in a gutter around the circumference of the roof of the main gallery and fed into cast iron pipes that drained the water into ceramic pipes leading to the cisterns. Water from the cisterns was then retrieved by a handpump next to the sink in the galley.

Today, the basement holds supplies used by the Trust. There are also two banks of batteries, charged by the solar panels that were installed nearby on the breakwater in August 2010. These batteries can meet the electrical needs of the entire lighthouse.

Due to the steep, narrow stairs and the presence of electrical equipment, the basement is not open to the public.

The main gallery provided the platform for entering the lighthouse and for loading supplies. The main gallery is 36 feet in diameter and was topped with a canopy comprised of 36 triangular cast iron plates hot-riveted together. The outside circumference of the gallery roof was ringed with a gutter to collect rainwater from the roof and channel it into the cisterns in the basement. Of three caisson lighthouses in Maine, Spring Point is the only one which retains its gallery roof.

The original cast iron plates comprising the main gallery roof were removed in 2004 due to corrosion and replaced with new plates made of steel. One of the original plates is currently on display on the main gallery.

The main gallery deck has two hatches on opposite sides of the lighthouse allowing access from boats. Adjacent to each hatch was a set of boat davits which held a dory for the keepers to travel to shore. A ladder beneath each hatch allowed the keepers to climb up from the boat and the bottom 10-12 feet of the ladder could be swung up out of the water. The bottom portions of the ladders were removed when granite was placed around the base of the lighthouse.

On the east side of the main gallery was located the privy, or outhouse. The sewage from the privy fell through a hole in the deck and into the bay. During that era, environmental considerations were not a factor. The privy was not present when the lighthouse was commissioned; how the keepers coped with that situation until the privy was built, we’ll leave to your imagination.

The galley is the level immediately above the basement and provides the only entrance into the lighthouse. An outer and an inner door were present, and a windbreak was built around the exterior door to keep cold air from blowing into the galley when the door was opened. It is not known when the windbreak was removed.

In the floor between in the outer and inner door is a hatch that, when removed, provides direct access to the basement. In the ceiling above the hatch is a large eyebolt, which allowed the keeper’s to attach a block-and-tackle to lower supplies into the basement, avoiding the precarious journey down the narrow, winding basement stairs.

The galley was the social center of the lighthouse where the keepers took their meals and relaxed during down time. It was modestly furnished with a table and chairs, a cupboard near the sink, a walk-in closet beneath the main stairs, a large cabinet topped with shelves, and some storage in the cabinet beneath the sink. Mounted on the counter next to the sink is the hand pump with which the keepers drew water from the cisterns in the basement for cooking, drinking, and cleaning.

Heat for cooking and warmth came from a coal stove. The brick walls are 24 inches thick at the base of the galley level and one can easily imagine the galley becoming quite hot when the coal stove was burning at it’s most efficient temperature. The galley was equipped with sash windows that could be opened for ventilation and they were probably the primary means of temperature control in both winter and summer. All of the sash windows were replaced with glass bricks for security when the lighthouse was automated. Above the coal stove was a vent that allowed heat from the stove to enter the head keepers’ quarters above, but that vent was later sealed off and the head keepers’ quarters provided with its own coal stove.

In 2013, the Trust commissioned a craftsman in Scarborough, Maine, to build a recreation of the cabinet and shelves that used to be in the galley. The original was removed by the US Coast Guard to provide for the underwater electrical cable to enter the lighthouse. The cabinet was moved to the lighthouse in two pieces by boat, hoisted up onto the main gallery, and reassembled. It is a welcomed addition to the galley.

The head keeper’s quarters is located one level above the galley. The head keeper enjoyed more privacy, since the stairs passed outside his doorway and he could close his door. His level was also provided with a walk-in closet beneath the stairs and a cupboard for storage. One assumes the keeper also had his personal bag or steamer trunk and perhaps a chest of drawers for additional storage while on duty. There is evidence that pegs or dowels were inserted into the brick walls to provide hangars for clothing or coats.

The furniture in both keepers’ quarters was most likely functional, but unremarkable, government-issue items: a bed or cot and, for the head keeper, probably a small desk.

The head keepers’ quarters is located one level above the galley. The head keeper enjoyed more privacy, since the stairs passed outside his doorway and he could close his door. His level was also provided with a walk-in closet beneath the stairs and a cupboard for storage. One assumes the keeper also had his personal bag or steamer trunk and perhaps a chest of drawers for additional storage while on duty. There is evidence that pegs or dowels were inserted into the brick walls to provide hangars for clothing or coats. Most of the furniture in both keepers’ quarters were most likely functional, but unremarkable government-issue items: a bed or cot and, for the head keeper, probably a small desk. In the ceiling adjacent to the center column is the shape of what was once a six-inch hole. This hole allowed the small weight from the lens clockwork to extend from the lantern room, providing room for the weight to move up and down as it was wound and the clockwork ran down, turning the lens. Like the galley below, the windows in the keepers’ quarters were once sash windows and could be opened for ventilation in the summer. The windows also provided convenient access to the top of the main gallery roof for maintenance and painting. The Trust has furnished the head keepers’ quarters with representative furniture to recreate the feel of a turn-of-the-century lighthouse, but the furnishings cannot be considered accurate as no photographs of the interior of the lighthouse have been discovered.

In the ceiling adjacent to the center column is the shape of what was once a six-inch hole. This hole allowed the small weight from the lens clockwork to extend from the lantern room, providing room for the weight to move up and down as it was wound and the clockwork ran down, turning the lens.

Like the galley below, the windows in the keepers’ quarters were once sash windows and could be opened for ventilation in the summer. The windows also provided convenient access to the top of the main gallery roof for maintenance and painting.

The Trust has furnished the head keeper’s quarters with representative furniture to recreate the feel of a turn-of-the-century lighthouse, but the furnishings cannot be considered accurate as no photographs of the interior of the lighthouse have been discovered.

The assistant keeper’s quarters were directly above the head keeper’s quarters and beneath the watch room. The assistant keeper suffered a lack of privacy, since anyone going up the the watch room had to pass through his room to get to the steel ladder leading to the next deck.

The assistant keepers’ quarters also marks the transition from brick construction back to cast iron. The brick wall here is about 20 inches in thickness. The watch room and lantern room continue the more traditional cast iron construction. Another marked difference the head keepers’ quarters is the lack of windows: the assistant keeper’s quarters used portholes similar to those in a ship. The main supporting column that runs through the lighthouse from the basement to the ceiling of the assistant keeper’s quarters also ends here, with six shims, like large washers, used at the top of the column to snug it up against the ceiling, which is also the floor of the watch room. Like the head keeper’s quarters, there is also the outline of a hole in the ceiling and floor adjacent to the center column, through which the weight and cable from the lens clockwork passed.

Furnishings, like those of the head keeper, were likely standard government issue. The assistant keeper did not have a walk-in closet like the head keeper because the stairs beneath which the closets were built ended at the assistant keeper’s door. He did have the same cupboard as the head keeper and almost certainly had a chest of drawers, along with his personal bag or trunk, for additional storage.

The assistant keeper’s quarters are now used as an exhibit room, with diagrams, photographs, and a lens on exhibit that give visitors insight into the lighthouse’s history and function.

The watch room was functionally the nerve center of the lighthouse, the gateway to the “business end.” The watch room of Spring Point Ledge Lighthouse was the office from which the light and fog bell were tended.

The watch room and lantern room above were where the lighthouse reverted back to all-cast iron construction. The lower wall is lined with beaded wood wainscoting. A clamshell-style cast iron door led outside to a gallery where the keepers could maintain the exterior portion of the Stevens fog bell apparatus and do whatever maintenance might have been required on the bell. Opposite the doors was a narrow window that looked west toward the city of Portland. Beneath the window was a small cabinet where spare wicks and other supplies were likely stored.

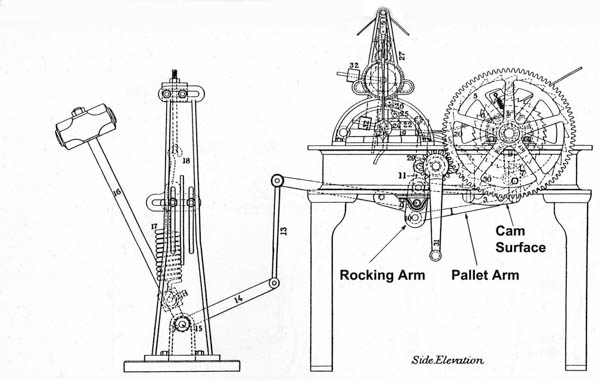

Most of the floor space of the watch room was taken up by the clockwork of the Steven’s Fog Bell Apparatus. The clockwork took up most of the center of the floor, with a weight suspended on a cable beneath the clockwork that passed into the center support column. The keepers also had to avoid the smaller weight and cable from the lens clockwork that passed through the watch room from the lantern room above and into the assistant and head keepers’ quarters below. More information on the Steven’s fog bell apparatus can be found in the Fog Signal section of our web site.

Today, the watch room houses the electronic circuitry for the lantern and the electro-acoustic fog signal. The sensor for the fog signal is mounted in the former window and the small cabinet beneath the window is no longer there. The cast iron clamshell doors are gone, replaced with interior and exterior wooden doors. For many years the watch room housed the battery bank that served as the backup electrical source for the standby beacon mounted on top of the mast that extends above the lantern room on the upper gallery. That battery bank was moved into the basement when the solar panels were installed on the breakwater in 2010.

In Maine, where fog is a very common occurrence during the winter, keeping the fog bell ringing was just as important as keeping the lamp lit. During periods of heavy fog, the light was often useless and mariners relied on fog signals to navigate and avoid each other.

Spring Point Ledge Lighthouse was served by a 800-pound fog bell cast in Boston the year before the lighthouse was constructed and which was purchased for $180. The bell was suspended outboard of the railing of the upper gallery on the lighthouse’s east side. The bell was sounded by a sledge hammer operated by an automated Stevens Fog Bell machine, which was purchased for $300. An additional $100 was appropriated to set the machine up at the Boston Light Station for testing while the Spring Point lighthouse was being built.

The Stevens Fog Bell apparatus was used in many lighthouses to ring a fog bell at a predetermined interval. The interval was determined by a set of cams and ratchets which made up the clockworks. A series of weights was suspended by a wire rope through the center column of the lighthouse. All the keeper had to do was keep the clockworks wound up. However, that was not as easy as it sounds because the weights could range from 200 to 800 pounds or more. These clockworks were advertised as good for 10,000 blows of the bell at one winding. The weights came in sections of 100 pounds each and the amount of weight applied determined the force with which the bell was struck. The Spring Point Ledge Light probably had a 200-300 pound weight. It is still in the center column in the cellar where it was dropped, along with the cable, when the Stevens fog bell apparatus was removed and replaced with an electric bell striker in the mid-1950s.

The weights lie jammed in the center column, where they were allowed to drop when the Stevens fog bell apparatus was removed.

At Spring Point, the bell was struck two times every twelve seconds. Spring Point’s fairly rapid interval probably meant that the Stevens apparatus could go almost a full day between windings. The apparatus was set up in the watch oom with a series of levers and pivots extending through the wall to position the striker (sledgehammer) to hit the bell with enough force to bounce back into the cocked position. There was no spring cocking system. The 800-pound bell was strong enough to withstand such strikes.

Prior to the invention of mechanical bell strikers, the keeper was obliged to manually hit the bell with a sledgehammer for as long as the fog persisted. Needless to say, many keepers hated this difficult, monotonous task and often ‘forgot’ to ring the bell during long periods of fog. Fortunately, Spring Point’s keepers were never faced with this arduous task, as the Stevens Fog Bell apparatus was installed during the lighthouse’s initial construction.

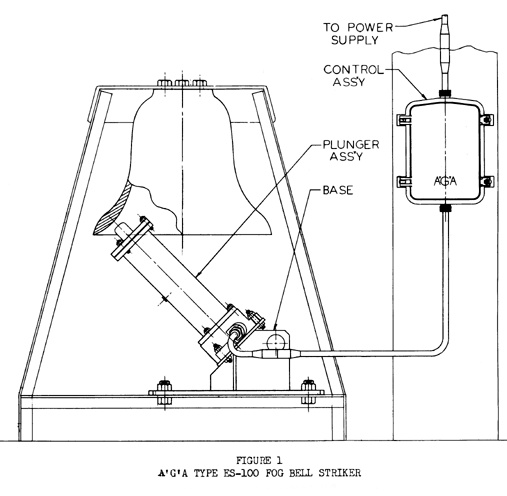

When the lighthouse was electrified, it allowed a more automatic method of bell ringing. An electric solenoid mounted on the base of the bell support frame was timed to strike the bell on an interval. The only job required by the keeper, by this time a Coast Guardsman, was to turn it on when fog rolled in. It could even be controlled by remote control, so a keeper was no longer needed. This system was used for a number of years until the modern electro-acoustic “hooters” entered service.

Spring Point Ledge Light now has two electronically-activated fiberglass fog signals controlled by an automatic fog detector which activates the fog horn when visibility drops to approximately one-half mile. This system works in both daylight and darkness and is effective in snow and rain as well as in fog. Because of their cylindrical shape, the electronic fog signals are jokingly called “R2D2s.”

The original fog bell is now on display on the upper gallery of the lighthouse.

The basement level of the lighthouse was also referred to as the first floor, even though we now think of the galley level as first. The basement is actually contained within the cast iron cylinder and, thanks to the height of the breakwater, visitors are actually standing even with the basement level when next to the lighthouse.

The basement is lined with brick to a thickness of around 24 inches. There were three small windows in the cylinder, but most have been sealed in recent years. There was also a hatch near the basement ceiling on the east side to permit coal to be transferred directly into the basement from a supply barge or boat alongside. There are also two small storage closets and a small room that might have functioned as a workshop or supply room for performing routine maintenance on the lighthouse

The center of the basement floor holds a cement pad that probably held either a compressor or a small generator. The actual use is uncertain, though the Trust is attempting to ascertain the exact purpose of the pad.

The most remarkable features of the basement are two brick-lined cisterns embedded in the basement floor. These cisterns held the only water supply for the lighthouse. Water was collected in a gutter around the circumference of the roof of the main gallery and fed into cast iron pipes that drained the water into ceramic pipes leading to the cisterns. Water from the cisterns was then retrieved by a handpump next to the sink in the galley.

Today, the basement holds supplies used by the Trust. There are also two banks of batteries, charged by the solar panels that were installed nearby on the breakwater in August 2010. These batteries can meet the electrical needs of the entire lighthouse.

Due to the steep, narrow stairs and the presence of electrical equipment, the basement is not open to the public.

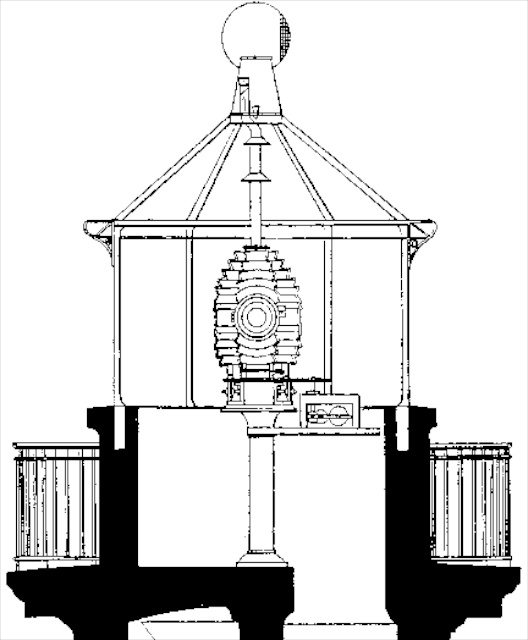

The lantern room originally housed the Fresnel lens, mounted on its bearings at the top of a pedestal, alongside of which sat the lens clockwork. The room was ventilated via small circular vents spaced along the lower wall, which drew air in and exhausted it through the ball vent on top of the lantern room roof. A small crawl-through clamshell hatch sealed with cast iron doors led out onto the top gallery. This enabled the keepers to clean the salt accumulation from the exterior windows, along with any soot deposited there from the tall chimney through which the coal stoves’ exhaust was vented.

Today, the lantern room holds only the light bulb carousel beneath the Lexan plastic Fresnel lens, mounted on a pedestal in the center of the small room. The original cast-iron doors are still there, along with the ball vent at the top. Nothing remains of the lens clockwork except for the sealed slot in the floor through which once passed the cable holding the clockwork’s weight.

The top gallery has the mast holding the battery-powered standby beacon that functions in place of the main lantern should a power outage occur.

The lantern room is currently suffering a substantial water leak, leading to considerable corrosion around the baseboard area of the lantern room wall. The Trust has been attempting to locate the source of the leak. An engineering study of the lighthouse structure scheduled for Spring 2014 should go a long way to pinpointing the leak so it can be repaired.

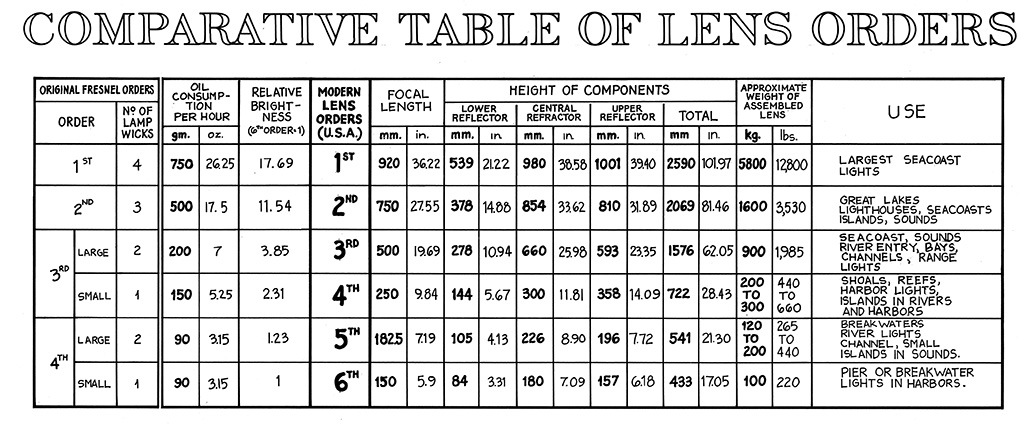

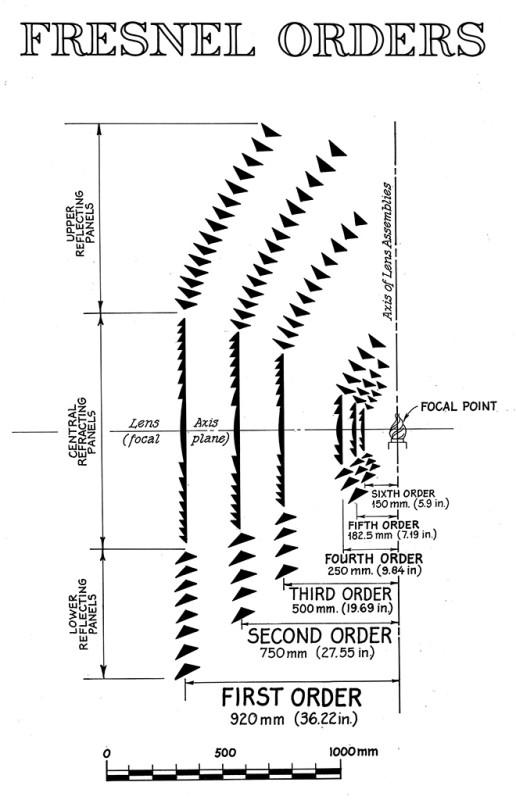

One of the most important improvements in lighthouses came with the development of the Fresnel lens. This lens, made up of multiple prisms which focus and amplify the light beam emitted from the lantern, revolutionized the lighthouse and increased its range and effectiveness for mariners.

The developer of the lens was an obscure French physicist, Augustine-Jean Fresnel (pronounced “Fraynel”), born in 1788. While assigned to civil engineering projects, such as roads and bridges, Fresnel developed an interest in light and began working on a method of focusing it.

Early lighthouses used a combination of a bulls-eye lens and a parabolic reflector to direct the light, an inefficient method that allowed light to escape at the top and sides. Later, refractive lenses were used to improve the light beam by bending it and directing it outward. Fresnel’s design combined the best of both of these features into a single lens. Using a bulls-eye in the center, surrounded by concentric rings of prism lenses, the entire assembly sent a bright, concentrated beam of light outward. Fresnel’s lens was readily adopted in Europe, but was late coming to America because of resistance by the Lighthouse Service. Eventually, however, the lens became the standard for lighthouses around the world.

Fresnel lenses are classified by size in a series of “orders.” The largest is the 1st-order lens, which is 8.5 feet high, 6.5 feet in diameter, and weighs 12,800 pounds. The smallest is the 6th order lens. Later, smaller sizes were added, but the original classifications remain the standard.

Fresnel lenses are extremely valuable, expensive to replace or repair, and their cleaning and maintenance are very labor intensive. For this reason, most of the Fresnel lenses in the United States have been removed from lighthouses and many are preserved in museums.

Today, only one 1st order lens remains in service on the East coast north of Virginia. Located at Sequin Island lighthouse near Boothbay Harbor, Maine, that lens is valued at over $8 million and attempts by the U. S. Coast Guard to replace it with a rotating beacon failed when public opinion forced the Coast Guard to abandon the plan.

In January of 1897 the Lighthouse Board approved $3200 for a 5th-order Fresnel lens and illuminating apparatus for Spring Point Ledge Light. The 5th-order lens was approximately 22-inches tall, 15-inches in diameter, and weighed approximately 265-440 pounds. To protect it from discoloration by sunlight, the lens was enclosed by a linen cover when the lamp was not being used.

A weight-driven mechanical clockwork mechanism rotated the lens to give the lighthouse its flashing characteristic. At Spring Point, the lens clockwork was operated by a weight suspended from a cable that extended through the watch room, the assistant keepers’ quarters, into the head keepers’ quarters.

Before Spring Point was electrified, the light was provided by oil lamps burning mineral oil. Oil was stored in the basement and only enough was brought up to the lantern room to fuel the lamps for the night.

The fifth-order lens was removed when the lighthouse was automated in May 1960 and a non-rotating 375mm drum Fresnel lens was utilized until the current 300mm Lexan plastic lens was installed. The whereabouts of the original 5th-order lens was a mystery until 2009 when it was located in a private collection in Michigan, where it resides today.

Spring Point Ledge Lighthouse was constructed much too late to use the whale oil that powered the early lighthouses. Instead, Spring Point used mineral oil, but exactly which type is unclear. The term “mineral oil” is widely and loosely used to describe several different types of oil, including those distilled from petroleum and those from other sources. The mineral oil used in Spring Point’s lamp was probably very closely related to kerosene.

The original lamp had a single wick on a base which held the fuel supply. The lamp was topped by clear glass, similar to those used on lanterns and hurricane lamps. This glass chimney vented into a metal chimney that extended upward from the top of the Fresnel lens to the ball vent on top of the lantern room and the smoke was vented outside through holes in the ball vent. This kept most of the soot away from the lamp chimney and the lantern room windows. Cleaning the inside of the lens, the glass chimney, and the inside of the windows of soot from the lamp was probably an ongoing part of the keepers’ duties. Later, the single-wick lantern was replaced with a mantle lantern which reduced the fuel burn to a pint and a half a night.

The lighthouse was electrified in 1934 and the kerosene lamp was replaced by a light bulb. When the lighthouse was automated in May 1960 and the Fresnel lens was replaced with a 375mm barrel lens, which did not rotate, the lightbulb was operated with a flasher.

Today, Spring Point light is powered by a small 36-watt incandescent lamp. The fact that it can be seen for about 14 miles, or roughly to the horizon line, is a testament to the resolving power of the Fresnel lens. Several of the small bulbs are mounted in a carousel mechanism that rotates a new bulb into position when the one in use burns out. The Coast Guard technicians replace the burned-out bulbs during routine maintenance inspections.